Vacuum Insulated Panel Ice Box

Cryolux VIP Shippers: The Future of Cold Chain Management

Revolutionize your pharmaceutical cold chain with Cryolux's innovative Vacuum Insulated Panel (VIP) Shippers.

The Challenge:

Traditionally, transporting temperature-sensitive pharmaceuticals has been a logistical nightmare. Thick-walled iceboxes, burdened with excessive ice packs, struggle to maintain precise sub-zero temperatures. These bulky solutions also incur high freight costs due to their size and weight.

The Cryolux Solution:

Cryolux VIP Shippers leverage cutting-edge vacuum insulation technology to provide unmatched performance and efficiency.

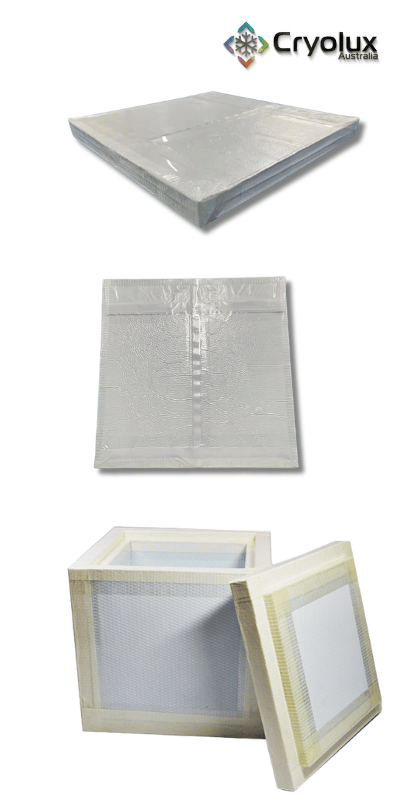

Unparalleled Insulation: Cryolux VIP panels boast R-values of 36, 12 times greater than standard polystyrene coolers. This translates to superior temperature control, even for sub-zero requirements.

Compact Design: Vacuum insulation eliminates the need for bulky walls and excessive ice packs. Cryolux VIP Shippers are lighter and more compact, minimizing storage space and reducing freight costs.

Durability Engineered: Cryolux understands the importance of handling during transport. Our VIP panels are carefully encased in protective materials, ensuring they withstand minor impacts.

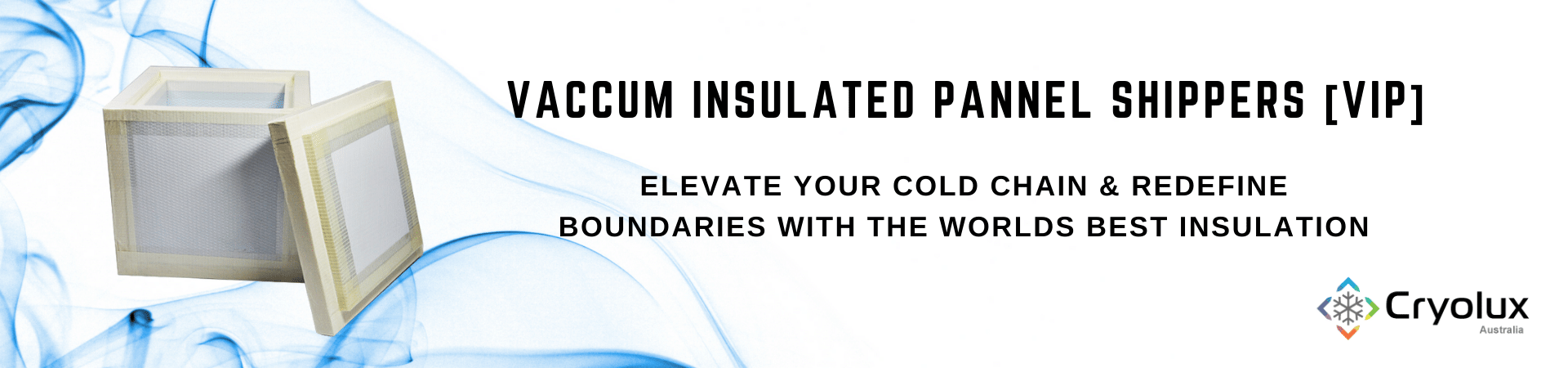

High-Quality Vacuum Panels: The core of Cryolux VIP panels utilizes high-grade porous materials, similar to open-cell foam or silicon aerogel. These materials are laminated with multiple layers of non-porous aluminum polymer film, creating a near-perfect vacuum. This ensures exceptional thermal performance.

Puncture-Resistant Design: Multiple film layers enhance the panel's puncture resistance, preventing leaks and maintaining superior R-values.

Enhanced Strength: Cryolux VIP Shippers are further fortified with high-density polyurethane, offering additional protection and improved structural integrity.

Extended Temperature Control: Cryolux VIP Shippers, combined with phase change materials, can maintain precise temperatures for over 7 days. This eliminates the need for frequent ice pack replacements.

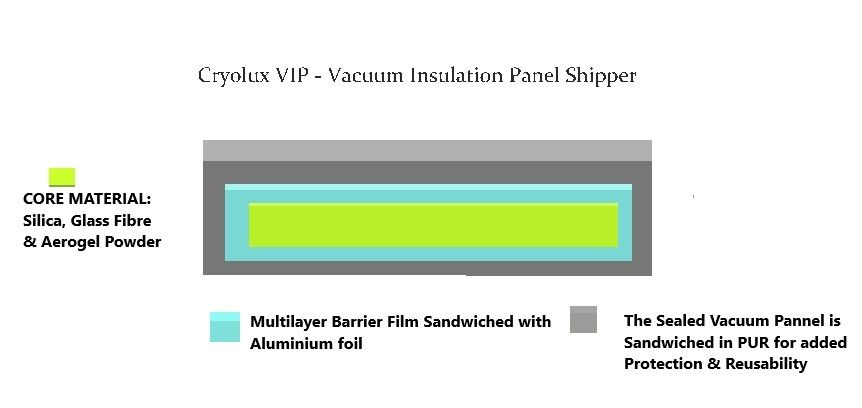

Flat-Pack Design: Cryolux VIP Shippers are designed for flat-pack return, minimizing return freight costs and environmental impact.

Cryolux VIP Shippers offer a future-proof solution for pharmaceutical cold chain management. Contact us today to discuss a customized solution for your specific needs.

Specifications

Item | Unit | Data |

Temperature range | °C | -100 up to 90 |

Bulk Density | kg/m³ | 160-250 |

Core Material | / | Fumed Silica |

Short-term withstand 110℃ | min | ≤30 |

Thermal conductivity (GBT 37608-2019 @ 25±2°C) | W/m.K | ~ 0.004 (no more than 0.0045) |

Size Tolerance | mm | ≤500 +1/-3 |

mm | >501~1000 +1/-4 | |

mm | >1000 +1/-6 | |

Thickness Tolerance | mm | ≤30 +1/-2 |

mm | >30 +2.0/-2 | |

Tensile Strength Perpendicular to Surface (GB/T 30804) | KPa | ≥80 |

Color | / | Silver |

- VIP Shippers -Vacuum Insulated Panel Ice box Shippers

- Light Weight, Easy to Handle, Compact Design

- Reduced Cube size Saves $$ on Freight Costs

- Best thermal Insulation helps maintain Temperature over 7 Days

- R Value - 36 ( Almost 10 times x Standard Insulation Materials )

- Most Reliable Insulation Medium for Non-Refrigerated Transport

Vacuum Insulated Panel VIP Shippers Cold Chain Esky Ice box

Vacuum Insulation Panel Coolers for Cold Chain Management

Transporting temperature-sensitive drugs in a non-refrigerated environment has been one of the biggest challenges the pharmaceutical industry has faced, costing them millions of dollars due to cold chain breaches. They have predominantly relied on extra-thick walled iceboxes that are overloaded with refrigerant ice packs and yet find the solution to be inefficient, especially when it comes to temperature specific specimens where they are required to maintain specific sub-zero temperatures. Invariably due to the large size of this type of cooler, because it has to accommodate the extra insulation and all the countless ice packs, the freight of these coolers gets very expensive. Thanks to vacuum technology known to be the best insulating medium, the coolers made using this technology are a saviour to this industry.

Cryolux manufactures a range of vacuum insulated panels that have R values of 36 which is almost 12 times greater than the standard polystyrene insulation. These panels are engineered with durability in mind. Since they are very brittle and need extreme care while handling, Cryolux has incorporated the vacuum technology to be sandwiched with other reliable materials to make them stronger and capable of taking minor impacts which are very common and expected during transport. Cryolux vacuum insulated shippers are not only lighter but also more compact, making them convenient to store and handle and also cost-effective to transport. These VIP shippers combined with the right amount of phase change material bricks can maintain the temperature for over 7 days. Cryolux has developed a range of VIP shippers that have been designed to be flat packed and transported back to the source hence making them cost-effective to freight back to the source.

It is important that the core of the vacuum panels have high-quality materials that are porous and have an open cavity similar to open-cell polymer foam panels or glass fibre foams and even silicon. Silicon code panels generally have a much longer vacuum life compared to the other types of vacuum panels. These materials are carefully laminated in multiple layers of aluminium polymer barrier film that is non-porous and vacuumed into a panel to avoid any leakage. The high thermal performance remains only until the vacuum exists in this panel. The moment there is a leak, The R Values of the insulation drops from 36 to almost 0. Hence multiple layers of the film are used to make the panel puncture-resistant thus preventing water vapour, nitrogen, oxygen, etc from leaking into the panel. To provide additional protection and improve the strength of the panel, it is further sandwiched with a high-density polyurethane.