Cold Chain Packing Tips | How to pack frozen things for transport

Cryophase Packing Tips & Recommendations

Cryophase Phase Change Material (PCM) gel bricks are highly efficient refrigerants designed to protect sensitive payloads from temperature fluctuations during transport. These PCM gel bricks and gel packs are engineered to deliver consistent thermal performance, making them ideal for cold chain applications where temperature stability is critical.

There are several environmental and operational factors that influence the temperature of the payload—such as the thermal properties of the Cold Chain Shipper, ambient temperature, humidity, and air pressure. Among these, the most influential factor inside the shipper is the performance and stability of the Cryophase PCM gel brick itself. Additional variables include the thermal mass of the refrigerant, payload temperature, refrigerant configuration, and correct conditioning of the PCM bricks.

Because of this, proper conditioning of Cryophase Phase Change Material bricks is essential to ensure they deliver optimum performance throughout the transport cycle.

Cryophase bricks are developed using high-conductivity hard plastic capsules that rapidly absorb heat and release cold energy uniformly within the shipper. Cryolux gel packs and flexible PCM icepacks are made using multi-layer barrier films that encapsulate the phase change materials securely while remaining flexible and lightweight. Both formats are engineered for long-duration, stable temperature control.

Cryophase PCM bricks are currently available in the following formulations, with ongoing research aimed at enhancing stability and extending duration performance across additional temperature ranges:

Cryophase sub-zero PCM brick range includes:

- Cryophase -5°C Phase Change Gel Brick

- Cryophase -10°C Phase Change Gel Brick

- Cryophase -12°C Phase Change Gel Brick

- Cryophase -15°C Phase Change Gel Brick

- Cryophase -20°C Phase Change Gel Brick

- Cryophase -25°C Phase Change Gel Brick

- Cryophase -30°C Phase Change Gel Brick

Best Freezer Preparation Tips for Freezing Gel Packs / PCM Bricks

To achieve the best results, it is important that the freezers used to condition Cryophase gel packs, PCM gel bricks, and icepacks operate at optimum efficiency. Most domestic freezers achieve a plate temperature around −21°C. However, their performance varies depending on maintenance, design, and load.

Recommended freezer preparation tips:

- Defrost and Clean the Freezer — Ice and frost build-up reduces freezing efficiency.

- Chest Freezers Perform Better — They maintain colder and more stable temperatures.

- Maintain Seals & Ventilation — Ensure door seals are tight and leave 3-inch space behind coils.

- Allow Airflow Around Packs — Spacing ensures uniform freezing and prevents distortion.

Choosing the Right Freezer for Cryophase PCM Brick Ranges

| Cryophase Brick Range | Minimum Freezer Requirement |

|---|---|

| Cryophase -5°C to -15°C | -21°C Freezer |

| Cryophase -18°C to -21°C | -25°C Freezer |

| Cryophase -25°C to -35°C | -45°C Freezer |

How to Properly Freeze Cryophase PCM Gel Bricks and Gel Packs

Cryophase PCM gel bricks, made from hard plastic capsules, can be easily stacked. Cryophase flexible gel packs should be laid flat and arranged carefully to prevent deformation as they freeze.

Always start with gel packs or PCM bricks at room temperature, not warm, before placing them into the freezer.

To ensure consistent freezing, freeze in rotating batches.

How to Condition Cryophase Phase Change Gel Bricks

Conditioning is critical for maintaining precise temperature control, especially for sensitive payloads. Cryophase refrigerants must start at the correct temperature based on the cold chain requirement.

When bricks must be colder than the freezer

Use freezing agents such as dry ice to reduce the core temperature further than the freezer allows.

When bricks must start slightly warmer

Monitor bricks with a laser temperature gun until they reach the required start temperature, e.g., −12°C.

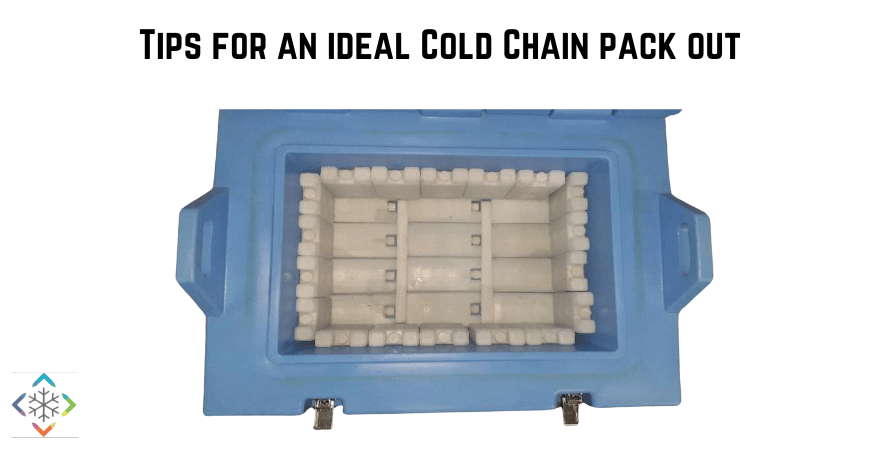

How to Pack a Cold Chain Shipper

Below are guidelines to maximise cooling efficiency when using Cryophase PCM bricks, Cryolux gel packs, or Cryolux dry icepacks.

1. Choose the Correct Shipper Size

Choose an appropriate cooler or Cold Chain Carrier to ensure sufficient refrigerant mass is present.

2. Correct Layering of Refrigerants

Use 1–2 layers of Cryophase bricks at the base and along the walls, packing the payload centrally.

3. Pack Quickly

Pack immediately after removing refrigerants from the freezer.

4. Seal the Shipper

Seal with insulation tape and store the carton in a cool area.

5. During Transport

Keep shippers away from frequently opened freezer van doors.

Cryolux Cold Chain Solutions

Cryolux offers a full range of gel packs, flexible ice wraps, Cryophase PCM bricks, and data loggers, alongside an expanding range of cold chain shippers.

For personalised guidance or technical support, please contact us at enquiry@cryolux.com.au.